OUR SERVICES

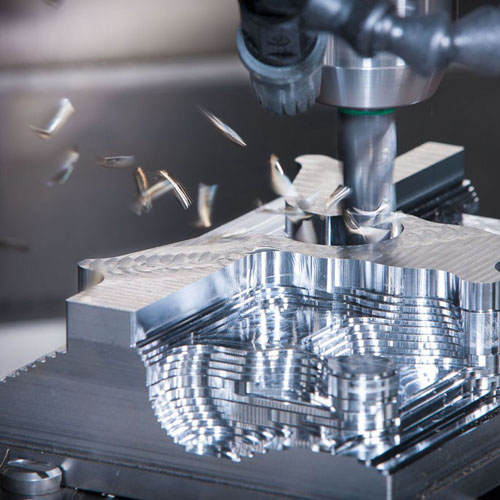

CNC MACHINING

CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc.

CNC as such can be applied in a huge variety of manufacturing processes and machinery. In this page we focus on machining operations that can be identified by their production of chips. This means the processes are substractive by nature and the equipment involved are oftentimes called cutting machine tools.

Referring to the page title, CNC machining can be defined as automatically and digitally controlled machining processes. Main machining processes include:

- Milling, where the spindle rotates removing material.

- Turning, where the cylindrical workpiece rotates while spindle is fixed removing the material

- Drilling, where a hole is cut into the workpiece

- Grinding, where a rolling, abrasive wheel removes light amounts of material

- Sawing where material is cut (into parts) with a blade.

- Finishing operations:-

- Filing that is about light amounts of material removing, combining grinding and sawing and is used mostly in deburring

- Polishing and brushing, where a smooth or shiny surface is created with abrasive process.

Our Machine

We offer wide range of service from CNC Machining to Conventional Machining.

CNC Turn & Mill (Mori Seiki), CNC Department - CNC Turning & CNC Milling, General Machining - Lathe, Milling, Grinding, Cutting, Welding & etc.

CNC Turn & Mill

CNC Department - CNC Turning & CNC Milling

General Machining

Get In Touch with Our Professional Team

Feel free to contact us and let us know what you are interested in.